Ageing Patina - Making Metal Look Like It Tells Stories

19 May 2025ageing patina,Vietnam,kitchenInspiration,Patina

Ageing Patina: the charm of making metal look like it tells stories. Ageing is also known as antiquing. We specialise in aged finishes.

What Is Patina? The Beautiful Art of Controlled Chaos

17 May 2025patina,verdigris,rust,what is patina,metal patina,antiquingPatina,Featured Projects,Metalier Water-based System,Inspiration

What is patina? It's the change that occurs to metal over time. Our patinas give nature a nudge to produce beautiful aged and rustic effects.

Liquid Metal UK - re-introduction!

6 May 2025Distributors,Inspiration,Metalier Water-based System,Metalier News

Liquid Metal UK -reintroduction is about it continuing in the safe hands of Granlyn Specialist Coatings.

In fact Liquid Metal UK has always been in Granlyn’s capable hands. In 2023 the business changed hands. The new owner and big boss is now Graham O’Neill. Graham has over 40 years of experience in the distribution of specialist coatings and is very excited about the development of the Metalier brand in the UK. Graham says “I was aware of Metalier through the previous owners of the business and have always been impressed with both the quality of the product and the endless potential. We don’t do boundaries. Only finishes.”

Architects & Designers choose Liquid Metal UK

Granlyn’s customers include Architects, Design Houses, Manufacturers, and Specifiers – all of whom are looking for inspirational products that can satisfy their customers’ requirements, and this is where Metalier fits the bill.

Granlyn, as Liquid Metal UK, can also apply Metalier if required

As well as the supply of Metalier products across the UK, Granlyn can complete in-house jobs where clients require this. Nigel ‘Ted’ Dexter is Granlyn’s Technical Manager and is responsible for the technical support of Metalier and the production of the in-house jobs.

Ted and Metalier go way back—he’s practically part of the formula!

And what’s the go for 2025?

Granlyn exhibited at the Surface Design Show in London, in February to showcase Metalier’s revolutionary water-based system. If you don’t know about the water-based system, you should. It’s a game changer.

Contact Graham

or Ryan

to learn about the waterbased system or to put Ted to the challenge.

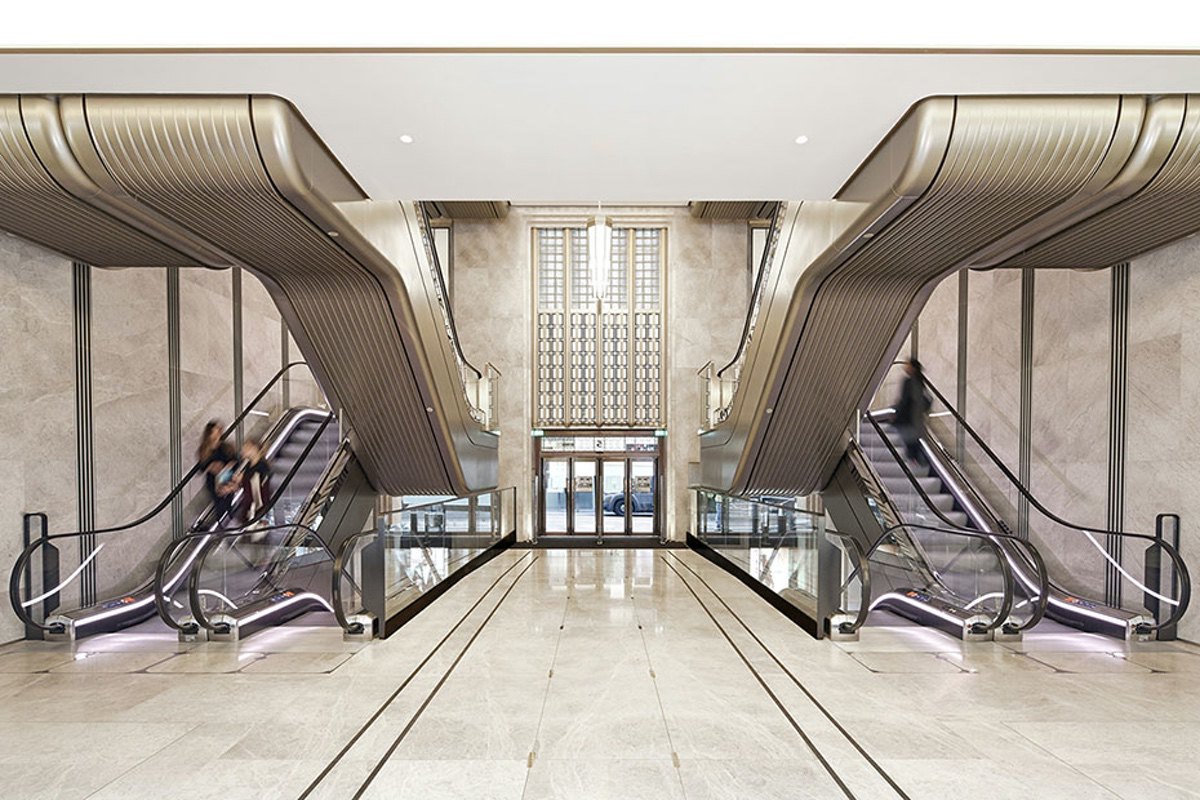

Bronze liquid metal

Bronze liquid metal curves

The bronze liquid metal reception desk is a standout piece in this fitout. We love everything about this design. The bronze liquid metal, of course, the sumptuous curves of the desk and the height of the reception area. Height is always a game changer in design.

A bronze liquid metal masterpiece

This magnificent piece was created by Metalier’s Creative Director, Richard when he was working in London. We’re very pleased that he is now working with us in Aotearoa/New Zealand. He’s pleased too. The main reason he wanted to work with Metalier is that we have created a robust and easy-to-work Water-Based Metal Coat – more on that shortly.

Metalier is a substrate expert

Here at Metalier HQ we have coated only works and substrates created by others – joiners, kitchen companies, door and window frame makers, and so on. Richard was responsible for making the reception desk as well as coating it. Those curves are his. He knows heaps about substrates – what works and what doesn’t. He’ll share the information with all specifiers and approved applicators of Metalier liquid metal. Just contact us if you have a substrate problem that you need help with.

Bronze is a favourite

Bronze has always been a favourite with the Metalier Team. It takes a patina well so that there are many looks you can create with the metal. Not only can patina work its magic, but we also have a deeper coloured bronze that we call smoky bronze. Both bronze liquid metal and smoky bronze are part of the 12 signature metals that Metalier now offers. There are other options – chocolate bronze and oil-rubbed bronze available on special order.

Learn some tricks from us

Bronze is also a helpful add-on metal. A little bronze added to brass will warm it up and disguise the hint of green that brass often has.

Contact us or your nearest distributor for more information or assistance. We love to help.

Brass Patination - Brass Windsor

20 August 2024Inspiration,Brass Windsor,Brass

Brass patination finish created for a fabulous project

The brass patination finish we created for Naumi Hotel in Wellington, New Zealand, was named Brass Windsor. The Naumi was reimagined as a riotously bold collection of gorgeous colours, textures and materials by our friends at Material Creative. It was an amazing project to be part of.

Brass Windsor

Brass Windsor

Brass Windsor has become almost the most popular finish in the Metalier range. We’ve included it in The Signature Range Finishes Collection that we are about to launch. We didn’t dare not include it – it would be like a chef changing leaving a favourite dish off a new menu. Not for the faint-hearted!

Brass is so popular

Brass has been the most popular metal we offer for over 4 to 5 years now. In 2023 some brave people predicted it was copper’s year. But that was not to be. Brass has continued to rule. And finishes using patination like Brass Windsor are the most loved of all.

Learn with Metalier

Learn with Metalier

The making of the finishes in the Signature Range has all been videoed and all the finishes have instruction sheets. All Metalier applicators throughout the world will be told how to create their own version of Brass Windsor. The process can be taught but the artistry in creating the finish will be the applicator’s own. Each applicator’s version of the finish will be unique to them. That’s what makes being a Metalier applicator so exciting.

If you think you’d like to learn about brass patination and other Metalier techniques contact us at HQ to be directed to your nearest distributor. We have distributors now in the USA and Canada, Australia, UK and India as well as NZ.

And we love to hear from you

Chemetal Sheet Metal

Chemetal sheet metal is now available again in New Zealand.

Chemetal sheet metal has been used in the past in New Zealand by many designers. It had established itself as a great light sheet metal alternative. Now it hasnew life and a new distributor for Austalia and New Zealand: That Metal Company of NSW and Metalier of Auckland have combined their metal ranges to give you a one stop shop for all your metal needs. The two products align beautifully and can be used together.

Chemetal sheet metal is a game-changer and here is why!

1. It is lightweight – 0.6 mm thick sheets in 2400 x 1200 mm & 3000 x 1200 mm sheet sizes.

2. The sheets bend to 90 degrees.

3. No special tooling is required. Joiners, cabinet makers and builders can use regular woodworking tools.

4. It is glued to an inexpensive substrate.

5. It is a cost-effective substitute for traditional sheet metal and ideal to use when you want a consistent pattern over a large area.

AND WE’VE SAVED THE BEST BIT UNTIL LAST!

6. It doesn’t tarnish. How good is that?

There is a huge range to choose from. It is divided into series #300, #600 #800 and #900. We love particularly the #300 and #900 series. This is because they are pure metal through and through.

The #300 series is real brass, bronze, copper and aluminium.

The #900 series is real aluminium anodized to look like brass, bronze and copper.

CONTACT US for the brochure that contains all the options.

AND if that wasn’t enough – this gorgeous sheet metal range is Class 1 Fire-rated and IMO certified. It also ticks all the sustainability boxes. It uses recycled metal, it’s manufactured using a solar energy system, it conforms to strict VOC emissions regulations and is PVC-free.

Decorative metal design

20 September 2021Product design,Furniture

We're expanding our decorative metal design

Expanding our decorative metal design reach through product design is one of the most exciting things we do. We love collaborating with designers to create ranges showcasing their skills and ideas using our finishes. The results have been stunning and very successful.

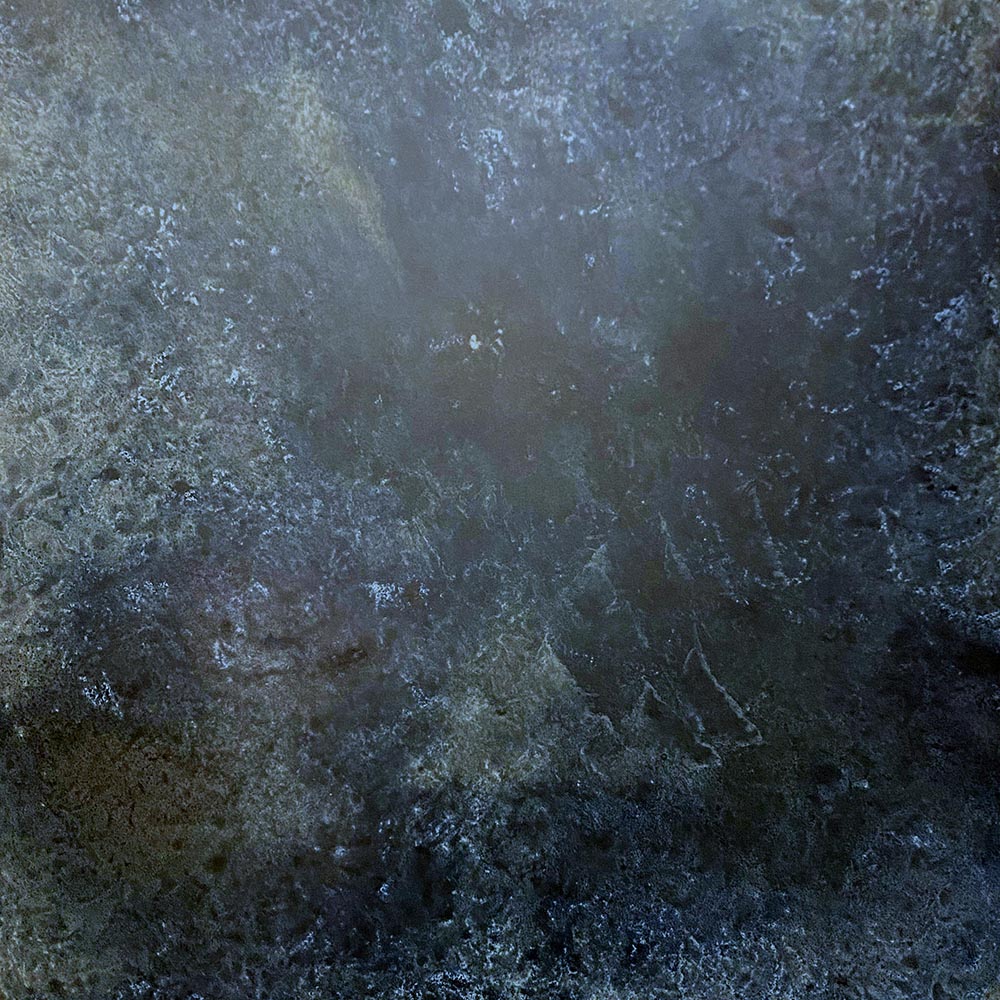

We've worked on beautiful light fittings, mirror frames, wall panelling and furniture. Our header image is of the sideboard called "Galaxy" and it is by David Shaw Furniture, a prestigious New Zealand company that designs its own range as well as importing exclusive international brands. It is fitting that this piece is called "Galaxy" as the finish Metalier created was independently called "Nebula". We were thinking along the same lines!

The picture left is of the really cute "Otis" tables in the same range. The top of the table on the left is Metalier's lightly-aged iron. The one on the right is the Nebula finish. We love the way the tables are slightly "wonky". This adds to their charm. Of course, if, for some reason Nebula doesn't appeal there are plenty of other options to choose from, including the ones we haven't thought of yet.

And here is a close up of beautiful nebula. We love the blue tones. The pattern and tones are created using patinas. Patinas are a key part of our creative process and you can read more about them here.

Right now we're working on light fittings and mirror frames and new panelling designs.

One of the exciting things for designers and their customers is that Metalier is a totally bespoke finish. No two pieces, even if created on the same day by the same person will look exactly the same. Add the variations of different days, different heat and different humidity and the variations can be even more dramatic. The result is that each piece is unique and the lucky end owner will know that no-one else has the same as they do.

Get in touch and tell us which way your design muse is leading you.

Let's talk about how can we bring to life your ideas and collaborate with you on something beautiful.

Wellcoll: Metalier European Master Distributor

23 January 2021Inspiration,Metalier News

Our European Master Distributor: Meet Wellcoll

Metalier Coatings and Wellcoll are delighted to announce that they have agreed that Wellcoll Group will be the Metalier European Master Distributor. Wellcoll is based in Sittard in the south of The Netherlands. In total it has six branches.

Wellcoll, like the UK Metalier distributor Granlyn Specialist Coatings, was originally concerned with the automotive business. Like Granlyn, it spread its interests, aptitude and knowledge into liquid metal. Wellcoll and Granlyn are in regular communication to ensure the best possible roll-out of Metalier Coatings in Europe.

Wellcoll knows liquid metal

Wellcoll, however, before it turned to Metalier used another liquid metal product. So they come to their role as Metalier European Master Distributor well-versed in the nuances of the product. Even though the technology is in the same family, Wellcoll has found huge differences in performance and handling. And the differences are all good ones. As Vital Verheggen Managing Director of Wellcoll said to us recently “we are so happy we have made the move to Metalier”. At Head Office, we’re happy too.

Wellcoll decided to join the international Metalier team in January 2020. And then came Covid! It took eight months to get the first order of stock to The Netherlands. From August 2020, however, Wellcoll has not looked back. It is now fully stocked, has its first brochure about to be printed, has its internet presence sorted out (click here) and it is open for business. In fact, it is already doing business and selling product and application knowledge to companies that are taking the technology in-house as an adjunct to their existing businesses. You can find out more on the Wellcoll website.

Get in touch

The first point of contact with Wellcoll is through its artistic and design director, Johan Gielissen. His telephone number is +31 88 758 08 87 and his email address is here. Johan can assist companies to take Metalier Coatings in-house. He is also the person to contact to discuss becoming an applicator or sub-distributor of Metalier’s liquid metal coating. At this stage, all the countries of the EU are open to opportunities. We do not expect that to last long.

Metalier Coatings are used by architects, designers, boatbuilders, kitchen companies, landscape designers and super-yacht designers. You will find Metalier Coatings in hotels, resorts, yachts, offices, retail and bars and restaurants and in homes. Metalier’s exciting and innovative finishes have been used often to create statement front entrances.

The opportunities are endless and the journey is an exciting one. To come along for the ride contact us now, complete the form below or contact your local distributor.

The Million Dollar Question for Metalier

18 March 2020brassBrass,Metals

The Million Dollar Question

For us the million dollar question has always been, how did you find us?

We always ask the people who contact us but the answer is always elusive. I was just “surfing the net” – right, what keywords did you use? What questions did you ask? I don’t know or, I don’t remember. Hey, we’re mighty pleased you got to us but we’d still love to know how.

Metalier liquid metal is an idea, a concept, that isn’t in the consciousness of most of our target market – architects and designers who would specify our products – and talented and artistic applicators who will apply and finish it.

Metalier is like metal veneer.

So how did wood veneer get started? It reminds me of an old joke about “The Happy Birthday Chicken”. What’s that? Nothing yet – but how do you think the Easter Bunny got started?

In days past people sneered at wood veneer because of what it is. Now, almost no-one would dream of using solid timber. Today people are using sheet metal when there are heaps of reasons why they shouldn’t – weight, cost, difficulty of handling, limited sheet sizes. The list goes on. But who knows to look for metal veneer?

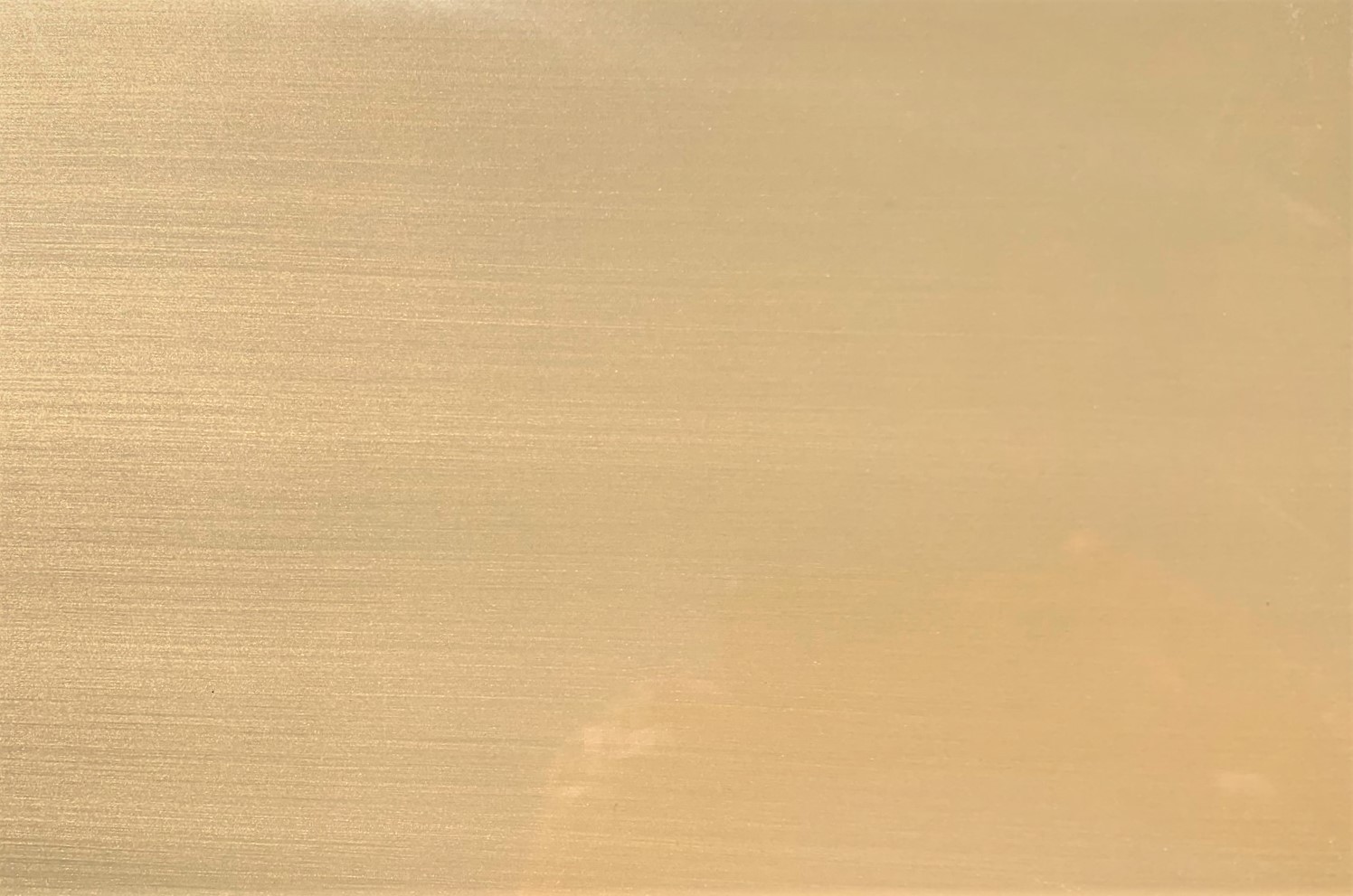

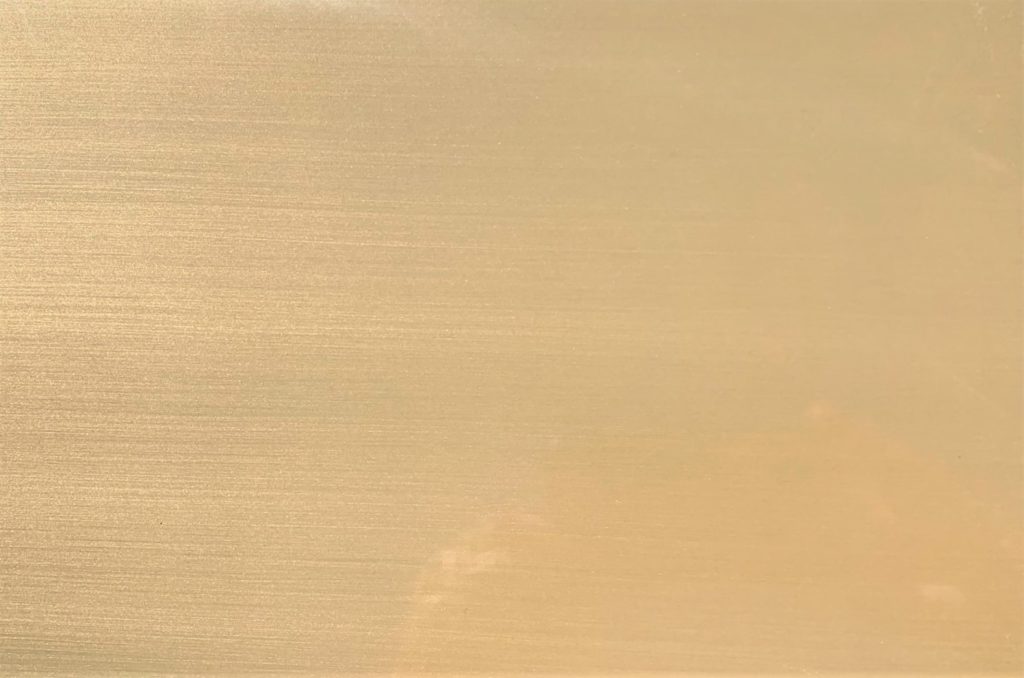

Brass/gold bring millions of dollars to mind

Which is why we chose our triple-polished brushed brass to feature in this blog. The website dark shadowing somewhat ruins the colour so here it is again. As is always the case, however, pictures never do justice to the brightness of real metal in the flesh – so to speak.

The million dollar question is a global one

Right now, the global growth areas for Metalier are India, the USA and Europe. And

no-one in all those continents can tell us how they found us. We keep asking ….

So, finding out what and why is a million dollar question with a million dollar answer.

If you can deliver the million dollar answer then, to coin a phrase,

we’re talking turkey, serious turkey.

So contact us via email, contact form, the telephone. Whats App, Facebook,

Instagram or Pinterest (not Twitter ☹☹)

with the code SERIOUS TURKEY and let’s talk – soon.

Talk to us or one of our hubs or complete the message form below.

Kitchen Design with Metalier

20 February 2020kitchen,brass,residentialInspiration

Kitchen design with metal

Being involved with kitchen design is one of our favourite things. It's a real treat to see the wonderful and innovative designs that usually first cross our paths as quote requests, then get into the workshop and finally are realised in the client's home.

In 2019 we worked on a fabulous kitchen design in a finish we have named water-aged brass. The brass was a real feature in the kitchen teamed with a stone bench and splash back. Although there was a professional designer involved in this rebuild, the client was very design-conscious herself and had strong ideas. Because of this she was a regular visitor to the Metalier showroom. It was a real buzz to work with her as we discussed the many options we could offer. The picture below is of the finished design. It looks stunning and our client is thrilled.

It goes without saying that she "gets" Metalier and was as keen to use as much of it as she could. As well as the kitchen we coated the statement front door in our brass moonrock finish plus two bathrooms in gunmetal bronze and another in rose pink.

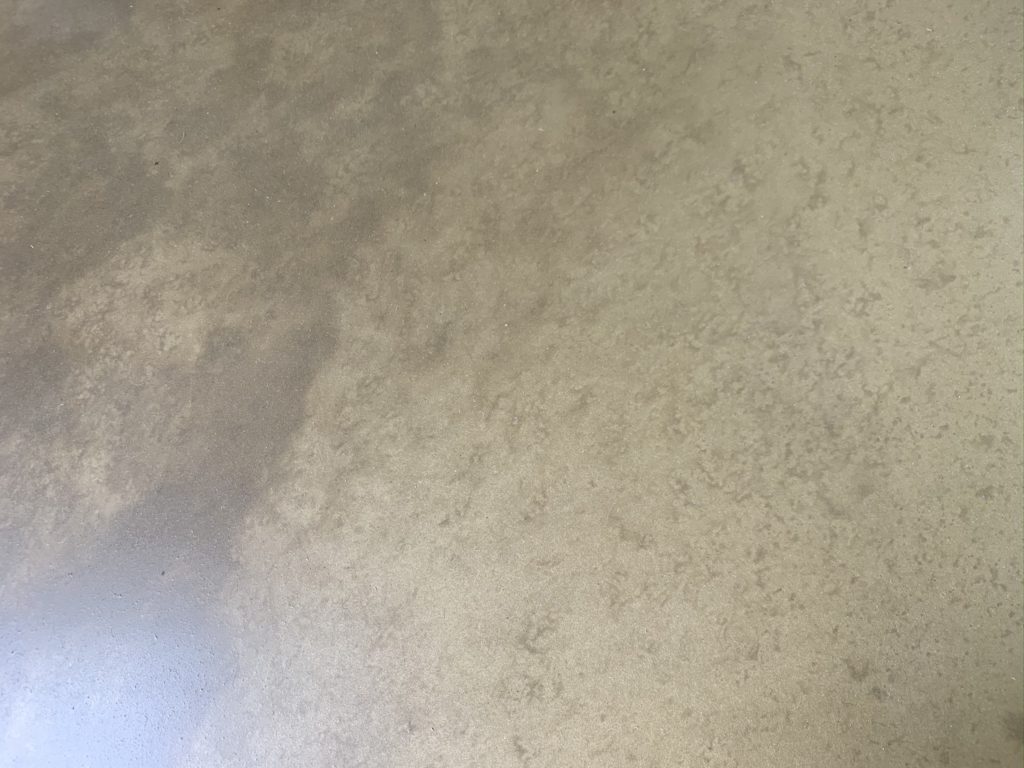

Water-aged brass

Water-aged brass is a new finish that our talented team developed. Without giving away all our secrets we can confirm that water was indeed a feature of the patina application. And in this case it was our Patina M16. A close-up of the finish is pictured below.

You may well ask why the colours of the two finishes look different. They are both brass and they are both patinated in the same way. Metal, however, whether sheet or our real metal coatings are notoriously difficult to photograph. The light plays tricks. The best way to see Metalier in the flesh, so to speak, is to request a sample.

Please contact Metalier through our hubs listed below or complete the enquiry form. And check out our other brass finishes here