Patina ideas with Liquid Metal

Patina adds a new dimension to metal

Patina is a thin layer which forms on copper, bronze and similar metals (as well as wood and stone).

It can add colour (think green Verdigris copper roofs) movement and texture. The picture on this page, is of the recently refurbished and extended Atomic Cafe in trendy Kingsland in Auckland, NZ. Metalier coated perforated MDF panels with copper and then applied a patina to age the copper. It adds a beautiful aesthetic to a great fit-out.

Many and varied effects can be created by patina

At Metalier we rely heavily on 3 patinas – M5, M16 and M 18 – so named simply because of their originating testing samples. As they produce different results on different metals we couldn’t give them a colour name like green patina (for example).

M5 on iron creates a red-brown rust. Iron rust is a very popular finish in New Zealand and the US. It’s not so popular in the UK. When applied to the “brown” metals, bronze, brass, copper and canyon (smoky bronze) a green patination effect is produced.

M16 creates an aged look in the brown metals and M18 creates various copper effects. When undiluted M18 creates a very dark colouring and when heavily diluted it creates a pearlescent effect – one of the most delicate finishes we can create.

Patinas are fragile and delicate creatures. They can be protected with our Nano clear coat but it is important to apply this carefully to avoid disturbing the patina and more importantly to reduce the colour changes that all clear coats invariably cause.

Different atmospheric conditions and various chemical compounds cause different colours – I know that. What I don’t understand is why the copper on two church roofs not 200 metres away from each other on Ponsonby Road in Auckland should produce such different colours – one is brown and the other green. The brown one is a lot older but I don’t think that’s the answer.

If you know why we’d be pleased if you’d tell us. You can read more about Metalier patinas here. We’d also be pleased to patinate your next church roof or coffee bar or hotel or bedside table? Contact us here or complete the form below.

General Contact Form

Cold spray metal coating | Metalier

Cold spray metal coating – choose any substrate

Metalier is a cold spray metal coating. Sometimes it’s good to get back to basics and explain exactly what Metalier Liquid Metal is and can do.

First – because it’s cold it can be applied to almost any substrate even the sensitive ones. Think polystyrene for example as well as the obvious candidates like wood, ceramics, mdf and fibreglass. The flexible coating can be applied to fabric and cloths of all types including leather. It won’t melt or damage the substrate.

Second – no heat is part of the curing process unless you are in a real hurry and using the HP Binder. This cures in between 12-24 hours without any assistance at all. But, as I say, if you are in rush you can shorten the process to 2-3 hours with the help of infra-red lamps. The water-based and flexible binders cure in about 4 hours and they don’t like to be heated. They dry by evaporation and heat can cause them to crack if you hurry them along too fast.

No baking and no ovens

So there’s no baking and no ovens, no need for heat protection for your workers. We were highly amused by one photograph that one of the competition had on their website. No names, of course, and they’ve since taken it down. It was however a picture of a guy all done up in the heat protective gear with what looked to me like welding gear. There was even a spark coming from the work. Who did they think they were kidding?

Because its cold, Metalier’s cold spray metal coating can be easily used in in situ applications. Read the pages about our binders, solvent high performance, water-based and flexible to see which binder suits your application. And you read it here first. We are about to launch a fourth type of binder. So watch this space.

If you have a comment about this blog or any of our other musings you can leave a message below the contact form. If you’d like to be notified when the new binder (it’s a water-based one too) please contact us here or complete the form below.

General Contact Form

UK Liquid Metal | London Success

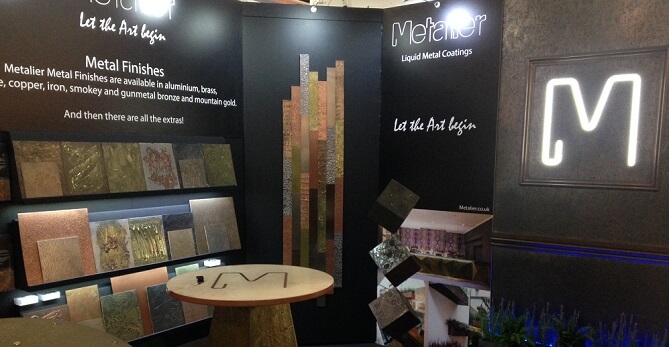

UK Liquid Metal stars at the London Surface Design Show

UK Liquid Metal is in the very safe hands of Craig and Alison McDonald of Granlyn Specialist Coatings. Granlyn has now exhibited at the London Surfaces Design Show for three years in a row. Every year its stand is brighter, bigger and better and this year was no exception. Once again, the Metalier stand was the star of the show. And we love Granlyn’s new strap-line “Let the art begin”. That’s exactly what Metalier is all about.

UK Liquid Metal’s stand featured Metal Coated Strand-board

It was coated strand-board that received the most comment and interest. It is an excellent example of how you can take an inexpensive material and with Metalier Coatings transform it into something amazing. This finish was featured in the Dior fit-outs in Auckland and Melbourne which were recently completed.

The Metalier stand also featured a polystyrene iron coated ball. Studded with magnets it demonstrates beyond question that this is real metal you are dealing with. It also looks so real that people lean on it. This can be a little interesting!

Lined up on the stand, dressed in Metalier Black, alongside Craig and Alison, was their Granlyn super-salesman, Steve. They need plenty of staff on hand as there are so many people who are impressed by Granlyn's creativity and want to know how they can be part of the world of Metalier.

Well done again team. At HQ, we all salute you and thank you for being part of Metalier International. Granlyn also does amazing work. If you haven’t seen The Leicester Grand Hotel you should check it out here.

To contact Craig click here.

To contact Alison click here

And to contact HQ click here or complete the form below.

General Contact Form

Bronze bowls | Metalier liquid metal

Metalier Bronze bowls were created by a design student

The bronze bowls created by design student, Shiri, resulted from her exploration of how traditional processes and materials could be complemented and extended using contemporary approaches - the best of the old alongside the best of the new.

The bronze bowls project were part of the second year Industrial Design and Innovation programme at AUT, Auckland. This programme is supported by Rebecca Dowie of Douglas and Bec. This company has been producing furniture and lighting since 2006. It has a particular focus on creators with an artisanal ethos who produce thoughtful, innovative work...an ideal fit for an AUT Studio project!

To create the bronze bowls Shiri used the precision that CNC cutting can achieve to form 'nesting' wooden forms. Her original plan had been to use cast bronze linings to her wooden bowls, but the cost to prepare and finish these, along with the weight led her to look for alternatives. Metalier cold sprayed bronze allowed her to successfully meet both practical and aesthetic objectives; the CNC lining was an exact fit to the inside of the wooden bowl, something that would have been far more difficult to achieve had it been done in conventional ways.

Michael Smythe in his recent book describes New Zealand Design as 'neither opulent nor sterile. It is accomplished with a light touch rather than a heavy hand. It delights in who it's for and how it's made. It is direct and to the point, and it doesn't take itself too seriously. It offers no 'bullshit' honesty with a twinkle in its eye..." Students were asked design more or less anything within the gamut of domestic ware, but to purposefully set about acknowledging these characteristics in their work.

An intelligent marriage of materials, sensitive use of form and materials in an unconventionally conventional bowl....a good example of Kiwi design?

Talk to us to see how we can help the twinkle in your eye. Contact us here or complete the form below.

General Contact Form

Metal hands | Metalier Liquid Metal

Metal hands caught Metalier’s eyes

Metal hands used as a handle in a dear little church in Little Akaroa, Pigeon Bay on Banks Peninsular, New Zealand, caught my eye on a recent visit to the South Island. The history of the church and the settlement in Little Akaroa is an interesting one. Bishop Selwyn visited there in February 1856 travelling in his mission schooner.

It is told that as the schooner’s rowing boat neared shore the Bishop called out “Do you know who I am? I am Bishop Selwyn, the travelling Bishop”. With that he leapt out of the rowing boat into waist deep water and helped pull the boat to the beach. We expect that he wasn’t wearing his mitre at the time.

The current church building which house the metal hands was built in the years 1905-6. It was built under the direction of a Mr Menzies who was a well-known local amateur carver “of the highest order”.

The outward appearance of the church is concrete with a pebble dashed surface. The church is designed in the well-known cruciform pattern with a little bell tower. It is well proportioned. Nothing on the outside prepares you for the inside however. The church is lavishly decorated in Maori form carving, White limestone features Maori carvings, the rafters are decorated with Maori patterns and there were Maori designs in the coloured glass.

It was unusual for this period to use Maori patterns and St Luke’s is one of the earliest European buildings to feature them. It seems that Mr Menzies did not consult local Maori who were somewhat put out about the use of their designs.

The little metal hands feature as a door handle on what looks like it could be the door to the choir vestry. Metalier can design and coat door handles to enhance any door. Just try us!

Contact us by telephone 021 732746 or complete the form below.

General Contact Form

Copper lace table | Metalier Liquid Metal

Evoque copper lace table

The copper lace table featured is the result of a design collaboration between Amanda Neill of Designworx and Metalier Coatings.

This copper lace table is the first piece in a line of tables Amanda has created as a collection. The design is typical of Amanda’s work – it is striking, it is “out there”, it is utterly gorgeous and it is very different. Amanda loves colour, boldness and everything exotic. It is exciting working with her and stretching the capabilities of the Metalier Coatings Amanda chooses to use.

This nostalgic and romantic copper lace table was created using real lace which is applied to the surface of the piece and over the edges. Metalier Coatings are sprayed through the lace to create the pattern. After curing the copper is polished and then patinated. A dark patina was applied to give the pattern an aged look. A green patina was used to create the Verdigris look in the stripe in that runs off centre through the table.

The finishing touch was Metalier’s Nano Clear coat which is applied in a very thin but robust layer. The nano clear ensures that the finish doesn’t oxidise beyond the desire look and it protects the surface.

The legs of the copper lace table are all hand lathed from solid wood. Each leg is different and each is finished in aged copper.

The copper lace table dimensions are 1000 x 1000 x 450mm. You can purchase the table through Designworx or by contacting Metalier directly.

Metalier has also competed a hall table in this collection. Three other pieces will be completed in the early part of 2016.

Metalier is always keen to work with designers and creatives to help them to realize their ideas. To contact us either click here or complete the form below.

General Contact Form

Metal Veneer | Brass | The Sugar Club

Metal Veneer | Brass showcased at The Sugar Club

Metal Veneer | Brass is showcased at The Sugar Club in the Sky Tower in Auckland City. It sits alongside sheet brass in a homogeneous glorious glamorous fit out. It’s a suitable background for Peter Gordon’s extremely scrumptious fusion food. One of our favourites is Beef Pesto. It was on the menu at Peter’s original Sugar Club back in 1987. His dining guests won’t let him take it off.

Metal Veneer | Brass in the private dining room

Private dining is the height of special. Metal Veneer | Brass is the outstanding decorative feature of the private dining area. Metal Veneer | Brass coats the MDF panels on the outside of the dining room and the inside too. A lovely cocoon of brass!

Even the Powder Room has a touch of Metal Veneer | Brass

The porthole surrounds in the Gent’s and the Ladies’ Powder Rooms are Metalier Liquid Metal Brass. You can bend sheet metal, of course, but the Metalier Solution of Metal Veneer in brass was more cost-effective and much easier to handle.

The Entrance Doors are Metal Veneer |Brass on a steel substrate

Metalier again shows its versatility on the grand front entrance doors to the restaurant. It is brass and glass. You can see them in the projects section of this website and on most of The Sugar Club’s own sites. If applying metal to metal it is necessary to create a barrier between the two metals to avoid osmosis occurring. The Metalier team are old hands at the procedure, however.

Just in case you didn't know, brass is an alloy of copper and Zinc. As well as being used in decoration brass is used in musical instruments for its acoustic properties. It is a very popular choice of metal currently and teams beautifully with white or black.

At Metalier Liquid Metal we have lots of ideas for creating beautiful things in brass – and other metals too.

Contact us to make your golden dreams come true.

General Contact Form

Metal Doors | Metalier Liquid Metal

Creating beautiful metal doors

Creating beautiful metal doors is one of the things we like best and do best at Metalier Liquid Metals. We enjoy it so much because it enables us to work closely with clients, designers and builders to create a special “Wow” feature for homes, apartments, offices, restaurants and shops.

Your involvement in the process can be as much or as little as you like. There is a door on the floor of the workshop in Henderson right at the moment which is very much a “hand’s on” project. Samples have been created which the clients love. “Awesome” was the word they used.

And just this week the designer has been in to mark out where she wants to locate the pattern lines. The metal being used - our smoky bronze is a sultry moody colour. The door itself is huge 2100 x 2200 – a total of 10 sq m including both sides and the edges. The door is going to be an indoor feature in the lounge/living area. And feature is the operative word. It is going to be spectacular. Pictures are promised.

Metal doors can be created using a variety of substrates

One of the benefits of Metalier is that it will adhere to almost any substrate. The only things which are “no go” are silicone, waxed objects and people! Metalier will adhere to anything that can be keyed to create a rough surface. We couldn’t do a Goldfinger James Bond lady, for example. (I was very disappointed to learn that death by gold painting was scientifically impossible.)

The most common substrates for doors, both indoors and out are wood and aluminium. Both deliver excellent results.

One of the things that gives us the most satisfaction is delivering to the clients expectations on budget and on time. And don’t think that a metal door is unaffordable. It’s not and we can show you how.

If you want to make a statement contact us by telephone or email or complete the form below.

General Contact Form

Copper and Iron together | Metalier Liquid Metal

A copper and iron mix – what shall we call it?

Copper and iron experimentation with rust have produced a beautiful new finish from the team at Metalier HQ. Actually it was Will, the Manager, who made the finish but everyone else chipped in with suggestions. To date we haven’t named it but suggestions have been Mars, Mars Sand, Martian and The Outback. We’re inclined to something leaning towards Mars. There has been recent strong evidence of water on the planet, and as we’re keen sky-gazers, we thought we should honour that discovery. You’d need some water to create the rust, perhaps?

Copper and iron together have medical associations

If you google “copper and iron” the first page is almost entirely taken up with medical and metabolism references. There is one reference, however by the Copper Development Association to the fact that copper has been used for many years to modify the properties of steel and cast irons.

Metalier’s interest in Copper and Iron is purely aesthetic, however.

The new finish is elegant, it blends high polish with rustic rust and allows the rust to look very sophisticated. We can’t wait to see it on a reception desk, or lift doors – maybe a fireplace surround or on a super yacht. We still can’t help being amused by the audacious designer who put rust next to white velvet in the saloon of a super yacht. The contrast of styles and aesthetics was just stunning.

It sounds like a cliché to say that the options with Metalier are unlimited but it is actually true. If we provided samples of every finish we’ve ever done the sample boxes wouldn’t be 19cm long (that’s 7 ½ inches for Americans and old people) they would fill a whole bookcase – a bit difficult to lug around for presentations.

If you would like to tell us what you think we should call this new finish or order it, or something else for yourself, please contact us or complete the form below.

General Contact Form

Opera Stage Sets | Metalier Liquid Metal

The opera stage set is an important part of the art

At Metalier HQ we’re very interested in opera stage sets and opera stage design. In fact we confess that opera is our favourite type of classical music. (We’re fond of Leonard Cohen, Bob, Fleetwood Mac and the Beatles too.)

Living in New Zealand we don’t get much live opera so we’ve been devotees of the Metropolitan Opera Live in HD series. This series, which you view at a cinema, takes you to an opera at the Metropolitan Opera in New York. A live performance at the opera is filmed and transmitted immediately to a live audience at many places round the world. It is also recorded of course and the recordings are played in cinemas. That’s what we go to see.

Most of the popular operas have already been performed including Wagner’s Ring Cycle. One of the operas took 6 hours and we had to have a dinner break in the middle.

The opera stage set for the Ring Cycle was captivating

The opera stage for Wagner’s Ring Cycle was deceptively simple and modern. It involves 24 identical wedges which are able to rotate independently on a horizontal axis across the stage. This provides level, slopping, angled or moving surfaces facing the audience. Bubbles, falling stones, fire and all sorts of colours are projected onto these surfaces. The visuals are linked by computer with the movement of the characters and the music. Just magical!

Rhine maidens could slip down the blue slopes of the surfaces – in fact it looked very slippery. The Valkyries rode them like horses. It’s impossible to describe the effect in words but you can watch the opera stage in action on this Youtube video of the Ride of the Valkyries.

And the relevance to Metalier you ask? Well it looks very much to us that the opera stage is made of metal. Indeed that’s logical because only a shiny surface would be able to reflect the light, flame and bubbles sufficiently. We rather fancy doing an opera stage set or maybe a movie set so if you’re thinking about creative we’d love to hear from you. We like the Valkyries' metal costumes too - Metalier Flexible metal could be the go here too.

If you want to talk to us about your next creative idea, musical or otherwise, or want to talk to us about opera or even sing to us you could contact us or complete the form below. Either way, we’re looking forward to it.